Situation

Emission-controlled areas require the reduction of sulfur emissions, which leads to fuel changeovers from heavy fuel oil to light fuel oil

Reliable operational safety and long runtimes in the field of ship technology with the DF-M7

Emission-controlled areas require the reduction of sulfur emissions, which leads to fuel changeovers from heavy fuel oil to light fuel oil

Lack of lubrication and constantly changing operating conditions

Significant runtime extension thanks to the use of DiamondFace technology

ECAs (Emission-Controlled Areas) were established a few years ago in the North Sea and Baltic shipping areas, the English Channel and the US and Canadian coastal regions. Ships that operate in these waters must reduce their sulfur emissions to 0.1 % m/m. While heavy fuel oil (HFO) is used as a fuel outside these ECAs, ships switch to light fuel oil (MDO - Marine Diesel Oil) with its lower sulfur content within the environmental zones and in harbors.

These fuel changeovers are particularly frequent on cruise liners, which often go to new destinations every day. This puts considerable strain on machines and components, including the booster pumps that transport the fuel from the bunker to the ship’s engines under pressure - and consequently the mechanical seals in these pumps, which are designed for stable operating conditions and continuous lubrication of the seal faces.

The seals applied to seal the pump shafts are exposed to extreme stresses due to the lack of lubrication of the seal faces and the constantly changing pressure and temperature conditions.

In addition to the changes between HFO and MDO, the quality of the heavy fuel oil also has a negative effect on the lubrication required for the seal faces, and thus on how reliably the seals function. In HFO operation, water vapor can be mixed in with the fuel to reduce the amount of soot in the exhaust gas. Furthermore, HFO can contain up to 30 % of substances that cannot be defined more precisely according to current standards, and thus can potentially impair the seal. In addition, temperature jumps of around 70 °C (126 °F) occur at the booster pumps and their seals during fuel changes.

Since the vertical screw pumps used have mechanical seals installed at the top, gas building up in the seal compartment can also cause a lack of lubrication. Furthermore, the temperature limits for the FKM (fluoroelastomer) secondary seals applied as standard are regularly exceeded.

The operating conditions immediately suggest the application of double mechanical seals, but this is often impossible due to the limited installation space and is undesirable on cost grounds.

Conventional mechanical seals used to achieve a limited service life of 50 to 500 operating hours before unacceptable leakages occurred. This contrasts sharply with the operators’ demand for a MTBF of 8,000 hours.

Early wear of the mechanical seals thus caused massive problems for shipyards and cruise ship owners. Time and time again, the unavoidable replacement of seals resulted in a lot of time and money being spent on maintenance.

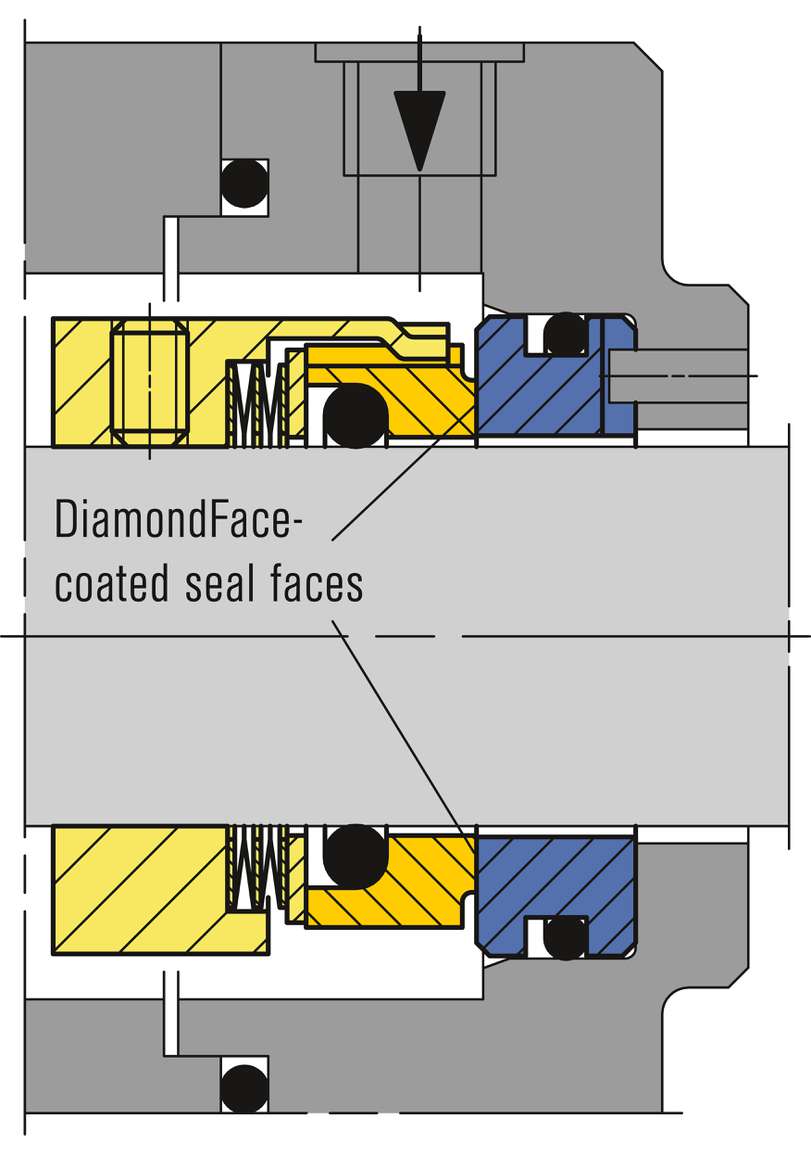

Illustr.: Rotating unit of EagleBurgmann type M7 mechanical seal. This universal shaft seal has proven its worth millions of times over.

EagleBurgmann DiamondFace is the key to solving such sealing problems. The positive experiences gained from other applications, such as high tolerance to dry running and significantly longer service life, are impressively demonstrated yet again in these applications.

The four booster pumps in each of five cruise liners operated by one of the world’s largest ship owners have been equipped with type DF-M7S91 single mechanical seals coated with DiamondFace since 2011. While the pumps in the first two ships were retrofitted, the DF-M7S91 seals in the other three ships were installed while they were under construction in Papenburg, Germany.

These 20 seals with the high-tech coating have been working perfectly and without a hitch since commissioning. The massive leakages that used to occur have been eliminated and reduced to a minimum. Running times of up to 10,000 hours are now achieved by the M7S91, promoted by its extraordinary tolerance to dry running and the extreme chemical resistance of DiamondFace. This is combined with never before achieved MTBF values, much to the operator’s satisfaction.

Illustr.: Single mechanical seal DF-M7S91. The seal faces of the rotating ring and stationary seat are diamond-coated. Yellow parts = rotating, blue = stationary, gray = housing

The solution for reliable operational safety and long service lives for mechanical seals under heavy-duty conditions

Between June 2017 and March 2019 the Hengli Group constructed an integrated refining and chemical complex in the Chinese harbor town Dalian where 20 million tons of crude oil are processed every year. EagleBurgmann advised the company Hengli concerning the selection of mechanical seals and supply systems for the whole plant and supplied more than 95 % of the components in use.

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

Things get hot in rotary kilns, very hot in fact. In the production of cement, for example, the thermometer measures more than 1,000 degrees Celsius. Sealing systems from EagleBurgmann, a company of the Freudenberg Group and EKK, make sustainable contributions to environmental protection, energy efficiency and process reliability under these "fiery" high-temperature conditions.

Our modern civilization is quite literally built upon cement. Today, building materials made from cement are used in buildings, roads, bridges, dams etc. Cement production is a heat-intensive process and causes thermal expansion in duct systems. To compensate this, Indian cement producer Ramco Cement needed fabric expansion joints with a diameter of several meters for two of their plants. On the basis of a close collaboration, EagleBurgmann was able to design components that increase the efficiency of the plant in the long run.

Seals are a risk factor in the production of liquid crystals. If there is even the slightest contamination of the liquid crystals, this will later affect the image quality of the display. Read on to see which sealing solution Merck KGaA uses in paddle dryers for the production of liquid crystals.

Cruise liners have to reduce their sulfur emissions in Emission-Controlled Areas (ECAs). To accomplish this, light fuel oil is used in coastal regions - with significant consequences for the ship's fuel supply.