Seal Management System - SMS

Seal Management System - SMS

Example of a SMS gas supply system to supply a compressor with 2 tandem seals with intermedia labyrinth.

| Item | Description |

| 1 | Compressor |

| 2 | Main seal |

| 3 | Separation seal |

| 4 | Flushing gas module |

| 5 | Barrier gas module |

| 6 | Separating gas module |

| 7 | Leakage module |

| 8 | RoTechBooster module |

| 9 | Gas conditioning system IN |

| A | Primary seal gas supply |

| B | Primary vent |

| C | Secondary seal gas supply |

| S | Secondary vent |

| D | Separation gas supply |

Seal Management System - SMS

Features

The EagleBurgmann SMS is a customizable system based on four modules. It is used to continuously supply and monitor gas-lubricated mechanical seals.

Advantages

- Reliable operation by supplying the seal with filtered and dry buffer gas, seal gas and separation gas.

- Condition of the filters, control valves, instrumentation and nitrogen and process gas sources are checked at all times.

- Constant monitoring for leakage and seal function.

- Individually adaptable to suit operating conditions and safety requirements.

- All current industrial standards, such as API and special operator requirements, can be fulfilled.

- Seal Management System (SMS) available with additional gas conditioning skid.

Standards and approvals

- Compliant to TA Luft (German Clean Air Act)

Recommended applications

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Chemical industry

Functional description

Flushing gas module

Primary seal gas line or buffer gas line:

Barrier gas module

Secondary seal gas line:

Leakage module

(Primary) vent line:

Separation gas

Separation gas line:

Primary seal gas line or buffer gas line:

- Supplying with filtered and dry flushing gas

- Monitoring and regulating the flow rate and/or the (differential) pressure

- Monitoring the gas filter

- For dual seals, process gas is generally injected in front of the seal as a gas buffer. The actual seal is supplied with nitrogen.

Barrier gas module

Secondary seal gas line:

- Supplying with filtered barrier gas (N2)

- Monitoring and regulating the flow rate and/or the (differential) pressure

- Monitoring the gas filter

Leakage module

(Primary) vent line:

- Monitoring of the leakage from the seal and outputting an alarm when the leakage is out of expected range

- Ensuring the leakage is directed to a flare or flare system

Separation gas

Separation gas line:

- Supplying and monitoring the oil barrier seal with nitrogen or air

- Monitoring and regulating the flow rate and/or the (differential) pressure

Notes

EagleBurgmann SMS are also available as complete conditioning skids with individually-adapted components, e.g.:

Other equipment and information available upon request.

- Booster

- Cooler

- Heater

- Separator

- Coalescence filter

- Demister

Other equipment and information available upon request.

Product variants

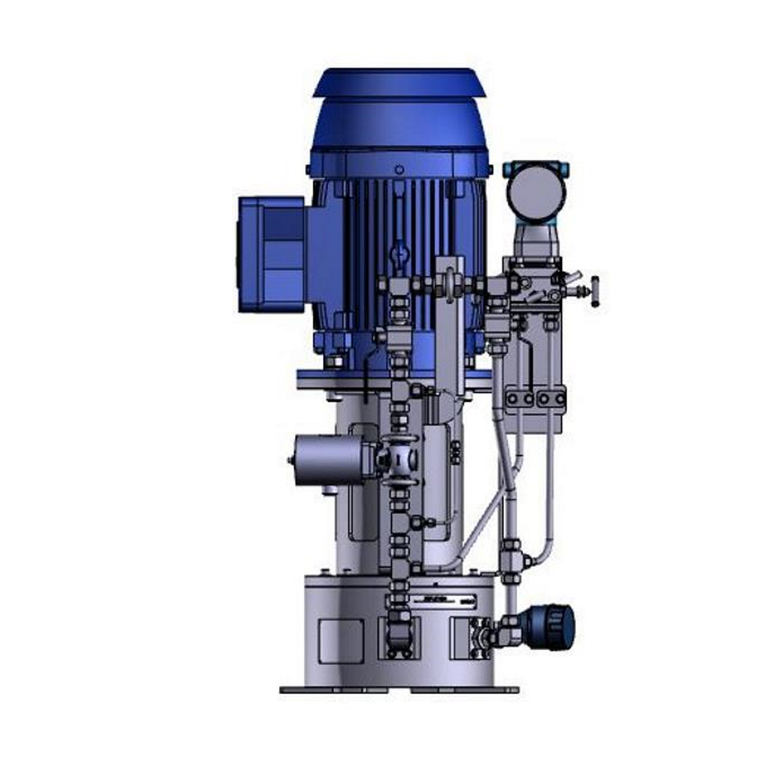

SMS gas conditioning skid with EagleBurgmann RoTechBooster

Gas conditioning system (skid)

| 1 | Gas IN |

| 2 | Cooler |

| 3 | Separator |

| 4 | Filter unit |

| 5 | Heater |

| 6 | RoTechBooster |

| 7 | Gas OUT - to flushing gas module |

Similar products

GSS Gas supply system

Gas supply systems of the GSS range are specially designed for contact-free operated, gas-lubricated mechanical seals. The gas supplied from the supply network (e.g. air or nitrogen) is regulated/monitored by the GSS in accordance with the requirements of the seals being supplied. The GSS systems are equipped with alarm and/or switch-off points depending on specific safety requirements. Centralized monitoring of the measurement values is also possible on request.

Circulation in accordance with API 682 / ISO 21 049: Plan 72, Plan 74

Circulation in accordance with API 682 / ISO 21 049: Plan 72, Plan 74

RoTechBooster

- Electric driven rotating design

- Hermetically sealed

- Delivers seal gas flow as defined by API 692

- 24,000 hours of operation before required maintenance

- Various models available, to meet specific requirements

RoTechBooster CX

- Standard model

- Plug-n-play

- Compact, electric driven rotating design

- Hermetically sealed

- Delivers seal gas flow as defined by API 692

- Continuous operation